Published on

Updated on

By Mariah Cox | Bond LSC

Fourteen days. That’s how long it took Sam McInturf and Ke Gao to put together a root imaging machine named ‘Sun Bear’ at the University of the Western Cape in South Africa this past June.

The pair, a postdoctoral researcher in the lab of Bond LSC’s David Mendoza and a computer science Ph.D. candidate, brought the automated approach to capturing data on root growth abroad as part of a technology transfer collaboration under the University of Missouri African Education Program (UMSAEP) established by the board of curators in 1985.

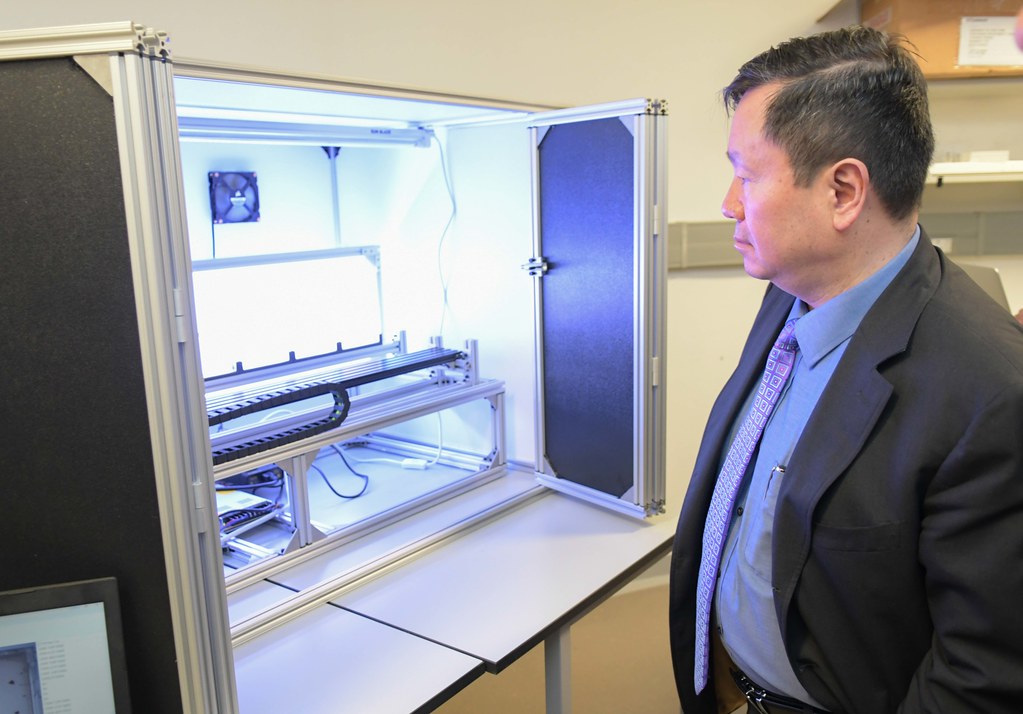

The machine, which optimizes data collection of root growth and provides more intuitive data about the factors that stunt or spur growth, allows researchers to focus more time on larger and diverse projects. In many research labs, automation is the way of the future.

“It changes the game. Being able to do everything in a high throughput fashion and being able to test lots of things at once allows us to consider the type of experiments we might conduct differently,” said McInturf. “All of a sudden we have access to the physical capacity to ask new types of questions.”

After touching down in Cape Town, the duo was immediately met with their first obstacle — the tools and building materials they shipped over were tied up in customs. Although McInturf and Gao prepared for obstacles with power conversions and tool availability, they weren’t anticipating broken equipment or problems with electrical wiring and motors.

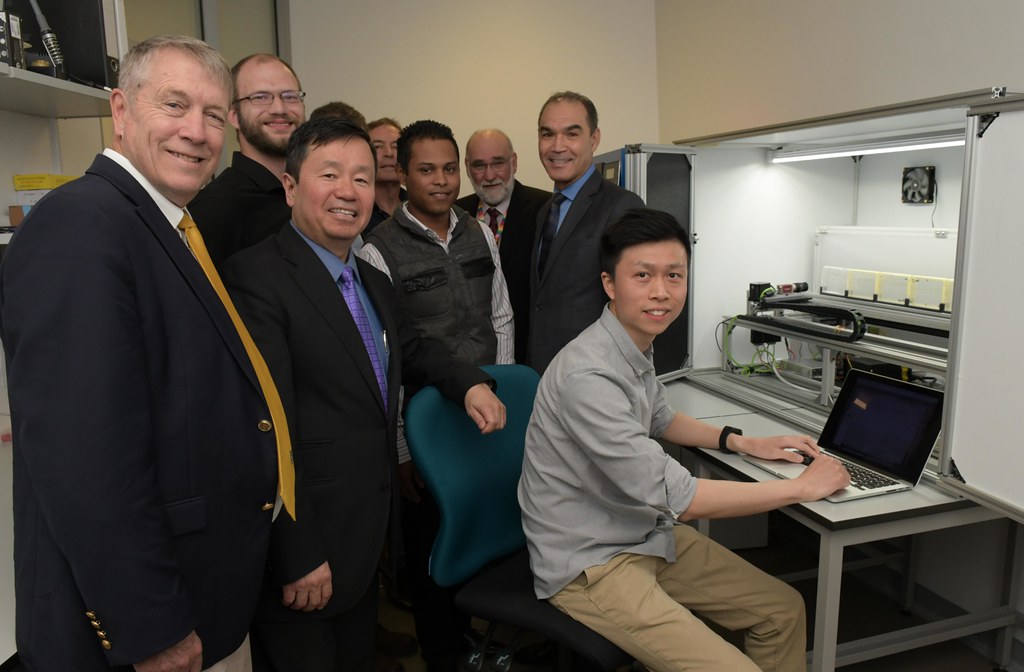

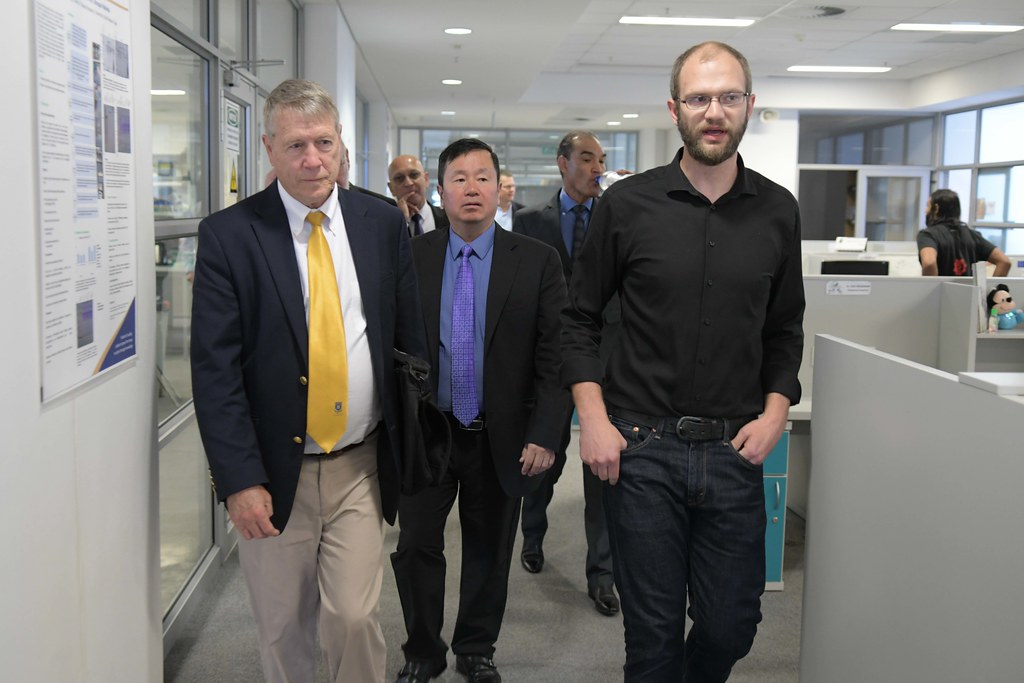

Over 14 days, the pair spent 10-12 hours in the lab constructing the machine in preparation for its unveiling with presidents and administrators of both UWC and MU. The construction of the machine coincided with a visit by the University of Missouri System President Mun Choi.

“We went over there with a hard deadline of presenting the machine to the presidents of both universities and we needed to be ready then,” said McInturf. “The sum total of all of our efforts resulted in 15 minutes with the presidents where we got to meet with them, and we got to show off what we had built and the plans that we have come up with for further collaboration.”

McInturf has been instrumental in the project since its beginning.

In 2014, the project idea was brought to McInturf by his adviser David Mendoza. Since then, the project has morphed through four major prototypes and has been worked on by students and researchers across multiple disciplines including bioengineering, computer science and computer engineering. In all, students and researchers from the Division of Plant Sciences and the Electrical Engineering & Computer Science Department spent five years developing the blueprint for the interface and the algorithm for the machine.

In its beginning stages, the project was part of a bioengineering senior capstone class, and McInturf was the only person working on it in 2017 as he finished his doctoral work.

“We made serious progress starting about two years ago, but we really hit our stride about one year ago in the fall of 2018,” he said.

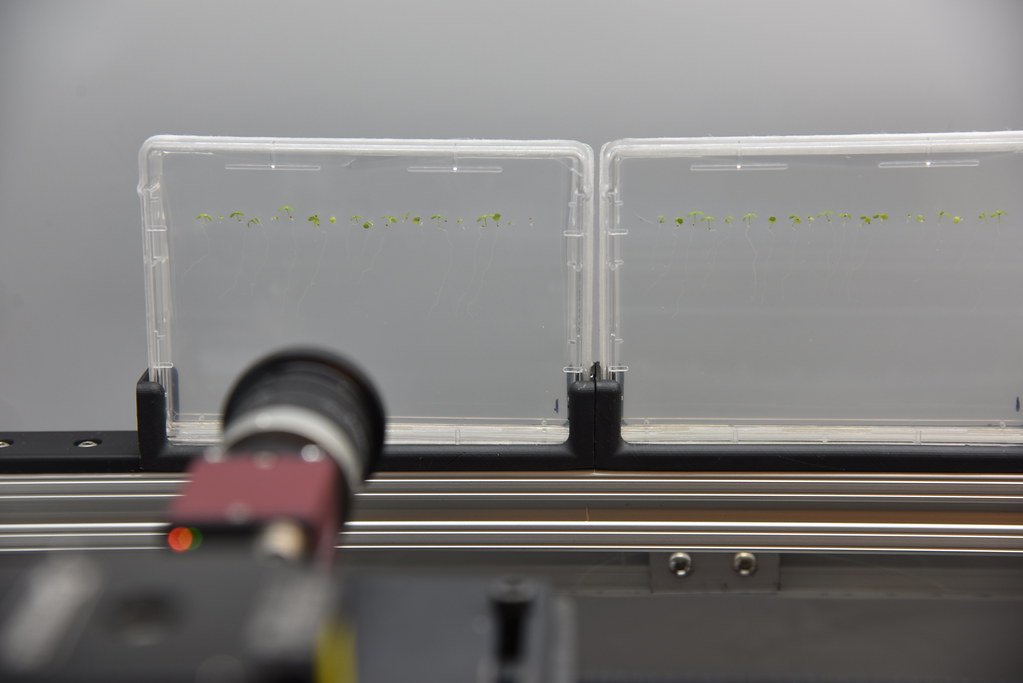

Gao joined the team about a year ago to help refine an algorithm to process the data. His algorithm recognizes the seed and the root and measures the root growth over time in conjunction with a time stamp.

However, the robot is still undergoing minor tweaks and finishing touches.

“We’re definitely going to be working on the root tracing algorithm for the fall semester. For now, it’s still a prototype. It’s not very optimized and it’s still a little bit slow,” said Gao. “I’ve been working with Sam to make the interface better to show more information like a graph or a table. Right now, we are only measuring the primary root, but there are also a lot of branches on the root. We don’t have an algorithm yet that’s working well for that scenario.”

The robot is currently being used at both UWC and MU to capture detailed information about root growth under a variety of different stresses, conditions and genetic backgrounds. This method of data collection as compared to the traditional methods of manually measuring and recording information is allowing researchers to better understand how different factors affect root growth.

“We are interested in characterizing genes by first breaking them and seeing what happens,” said McInturf. “Once we understand what these genes are doing and how they interact together, then we can go on to engineer crops and conduct targeted breeding strategies to allow plants to survive harsh environments.”

The project is part of a cross-campus collaborative named “The Foundry” funded by CAFNR and housed in the LSC which brings together scientists and engineers from varying disciplines to mechanize biology. Other projects currently being worked on by The Foundry include a hyperspectral camera and a leaf imaging robot.

As for McInturf, this project has opened his eyes to a new realm of possibility in his future career path.

“I didn’t think that I could do this kind of work before this project. Not only did it show me that I have the capacity to do it and that it wasn’t so impossible, but it showed me that I could,” said McInturf. “As I move forward to industry or academia my goal is to be working on the interface between mechanization and plant biology, that is kind of my bread and butter at this point.”

UMSAEP was established in 1985 by the University of Missouri Board of Curators to aid South Africans who were disadvantaged by the then-government’s apartheid policies. In June 1986, a formal memorandum of academic cooperation was signed by then UM President C. Peter Magrath and then UWC Rector Jakes Gerwel. This agreement has the distinction of being the first-ever developed between a nonwhite South African university and an American university.